Wednesday, June 8, 2011

Braces & Floor

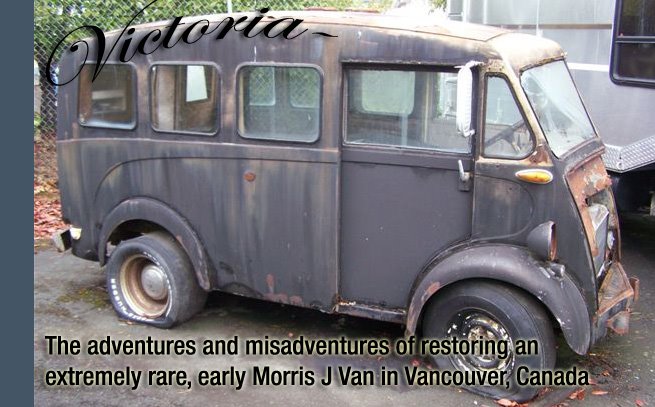

Last week and this week I took a weekday off and went to Aaron's shop for a few hours. In the first visit we attached the floor. By appearances the floor is pretty close to the original. The early metal floors were interlocking (kind of like Greek-key pattern) 16 gauge sheet metal. The interlocking was on the bottom side and, for this reason, the floor frame (the one that's wood on later vans) has these notches taken out of it. The interlocking gave longitudinal rigidity for carrying loads. I'm not going to be carrying loads, so I just bent the metal downwards for about half an inch. Strong enough for my purposes. The bolts that I used are correctly located and pretty close to the originals. The originals were flathead 1/4" with a little flush washer. In the second visit (today) we installed the braces on the side. I expected it would be a big hassle, but it was no big deal. The original braces are 1/4" less wide, but the same patterns as the ones I used here. I think they look awesome. Finally, I went over to Steve's house on the weekend and started removing pieces of the engine cowl. I'm going to take it over to Austin and have them fabricate an authentic-looking replacement. Above is a photo of Steve's van with the from removed. It's a rusty beast.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment