I expected in the course of having the bodywork done there would be setbacks and surprises and, in the last week, I got both. The upshot is that I don't have a lot progress to report for the greater worldwide J Van fraternity. First, the next time someone goes to Iain Mckenzie's place, I want them to check the size of his brake. Is it more than four feet? I suspect not. That's why, for instance, the drip piece for the rear doors is perfect except for the last 4 inches or so. Because Iain's brake was too small for the job, he seemingly made the part in two pieces and then welded them together. The result is so crappy that I cannot put it on my van. I'll post a photo later. What irks me is that I paid to have that piece of crap shipped from 9 times zones away. Meanwhile, there were some made in Canada issues too. Today I met the guy who is doing the bodywork on the van (hereinafter referred to as "The Dude"). The Dude is quiet, but a very nice guy. Shy too.

The Dude has been doing his best to put together something very unfamiliar to him, and last week he went too far. He took the step well floor pieces and aggressively modified them to fit. Problem: he guessed how they fit wrong, and the result was that two additional pieces from Iain were toast. Aaron's agreed to make everything right, but two days were lost and the whole thing could have been avoided with a timely phone call. The Dude only works Monday to Wednesday. So today was really the first day of progress since last week and that's disappointing. When I left The Dude was making the LHD radiator mount panel to replace the RHD one that Iain made me wait 18 months to get. Does anyone want the RHD drive one? While I was there it was brought to my attention that Iain also made two pieces for the right-side front wheel arch, but none for the left-side one. However, he made up for it concerning the quarter panels. I got four instead of the two I ordered. Aaron's suspects that two "might" work out, but two others won't. Same story with the left-side panel below. Finally, the gutters for above the door are straight NOT curved like the originals (see photo above). So if you're counting the number of crappy parts received or missing from Iain amounts to six. Then there's other issues. The rear doors reskinned and sent me have wood jammed inside them to keep the exterior contour correct.

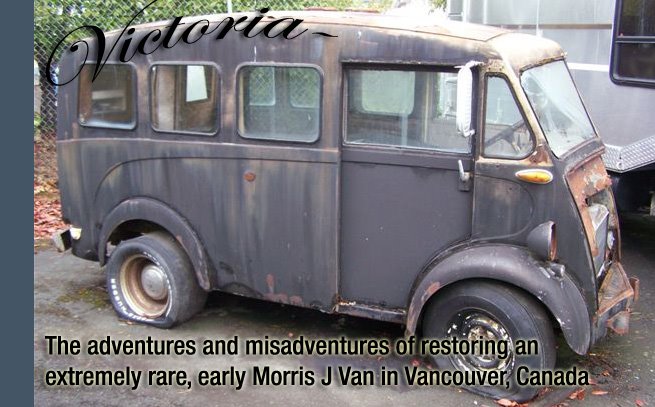

The "surprise" for the week is that the left "quarter panel" (the left rear corner of the van, if my terminology is incorrect) has a double skin. It appears to be a very old collision repair because it is seamless, and it is masked with lead instead of polyester resin.

As I type this I received Peter Bateman's Christmas greeting in the email (enclosed above). I thought to do something classy like that, but I don't think I could match the quality of the effort. So I did something that was within my means.

I'm two years and one month into the restoration effort. I've learned a lot and I'm nervous about the money I'm spending, but I like being a part of a tiny world community of J Van guys. To them, and others who just read this blog for curiosity, I wish happy holidays and a healthy and prosperous New Year. Also, if you're in Australia, keep your van out of the brush fires!

2 comments:

And a very big Christmas greeting to you too Charlie ... I read your blog with a great deal of interest, as I can relate to the performance by Iain, and sympathise completely with your low spots. However the highs must be enormous, as you are re-birthing Victoria and the light is shining at the end of the tunnel!

Charlie

You are doing a terrific job, we all know how much effort you are putting in, but at a show people will walk past and look for a minute and say terrific and keep walking - years of work summarized in seconds.

It is total lack of recognition

Cheers mate keep up the good work what you are doing is beyond my capability, but I can see countless hours of good work

Post a Comment